Here is the first edited video from the inaugural Westport Mini Maker Faire that occurred in Westport, Connecticut on Saturday, April 28, 2012. Many thanks to Gordy Waterman for doing the videography and the Westport Library for editing the video. Congratulations to some of the makers who are featured in the video, including: Nick Clarke, Breck Baldwin, Mike Ogrinz, Dalton Ghetti, Mike Staw, Alan Winick, Jeff Del Pappa, Balam Soto, David Pogue, Bill Derry, and Kerstin Warner. -Mark Mathias

Bio: Mark Mathias is the founder and co-chair of the Westport Mini Maker Faire. A technologist by profession, Mark is involved in numerous activities outside of work, including being in his third four-year term as an elected member of the Westport (Connecticut) Public Schools Board of Education, the president of the New York CTO Club, a member of the Westport Sunrise Rotary Club, and a member of the board of CLASP Homes.          Do makerspaces serve people’s wants or people’s needs? Certainly the vast majority of these spaces exist because people want to work on projects, learn from one another, and have access to shared tools. However, there is a small subset whose purpose is to address the needs of a community. This is the story of one such makerspace and the business model they'd like to spread. Maker Works is a member-based studio located in Michigan, the heart of the rust belt, where making has been a tradition for a hundred years but where hard times have tested the region’s character. We all know the story of the past decades where manufacturing jobs moved overseas, companies closed plants, and the population went increasingly underemployed. Times have been tough. It is in this context that Tom Root and Dale Grover found themselves.  Tom and Dale, dressed for making As with many makerspaces, Maker Works grows out of regular meetups of like-minded geeks. The first was a weekly breakfast called Go-Tech. Established and run by Dale, it quickly grew into a once-per-month evening show-and-tell where members shared their joy of making by wheeling in CNC machines, wiring-up Arduinos, and more. Dale went onto join a work space for laptop people known as Workantile, a co-working space. Then with three friends he established a hybrid model, a co-work space for entrepreneurial engineers which is known as A2MechShop. Traveling a parallel course was Tom Root. The downturn of 2008 hit his mail order business hard but while he weathered the storm he saw that many wouldn’t. He was seized with a sense that he needed to do something to help others. Passionate about the value of making, he decided that a makerspace workshop could help address big issues: unemployment, reskilling, self-sustainability, environmental, and other concerns. In 2008, after failing to entice TechShop to establish a local presence, he embarked on a path to build his own community workshop.

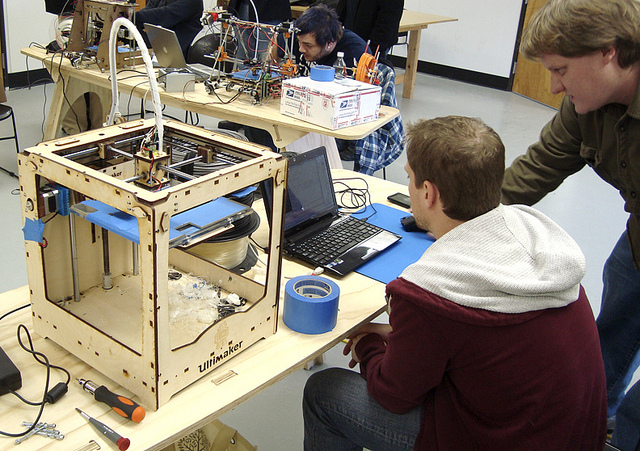

Over the course of the next two years, Tom navigated the waters of Go-Tech, Workantile, and A2MechShop with Dale. They got to know each other, found they shared values, and developed a common vision. With the passage of time and increasing confidence, in 2010, they decided to take the leap to establish Maker Works.  Metal Shop We need to pause here for a brief expansion on their shared values. Tom has spent 18 years running a company in a community of businesses called Zingerman’s. While the phrase "community of businesses" isn’t common, that’s partly the point. This group of co-owned businesses run by social entrepreneurs is on a mission to make a profit, to delight customers, employees and partners, and to do good for their community. Running a business to achieve good was second nature to Tom. As Dale learned more about Zingerman’s it appealed to him as he shared these values-based business practices. This common ground of running a business to achieve social good is the foundation of their shared ambition. (You can learn more about Zingerman’s here and from the book “Building a Great Business.”)  Wood Shop Now let’s get back to the story …It was early 2010. Dale and Tom had made the commitment to establish a socially responsible makerspace business to drive positive change. The countdown to launch had begun. By December they overcame a key obstacle; they found an insurer willing to underwrite the business. The next challenge was finding an appropriate space. Their initial goal was a 5,000 sq ft facility but they learned they really needed much more and eventually found an 11,000 sq ft facility near the Zingerman's campus. Not only were the terms advantageous because of the Zingerman's connection, but being close to Zingerman’s had many benefits. Maker Works could use Zingerman’s storage, borrow forklifts, buy at their stores, etc. while Zingerman’s could design and mill signs, build chairs, etc. at Maker Works. In February of 2011, Maker Works signed the lease. The makerspace business had a home! Preparing the space defined the next big push. Floors were carpeted and needed stripping, cleaning, and epoxy paint. Walls needed painting and there were so many walls! To quote Dale, it was “1640 linear feet of painted walls, but who's counting?!” Electricity needed to be distributed throughout the building to where it would be needed. Thank god for Toni, Tom's wife and partner! She wrangled all the vendors. The fathers of both Tom and Dale also deserve credit as they put in many hours building tables and more. Obviously, family was a key resource. Another key assist came from Karl Daubman, a professor at the University of Michigan. He is a principal at an architectural firm called Ply and is Chief Architect at a manufacturer of prefab homes named BLU Homes. He helped in a big way with permits, interior design, traffic flow planning, etc. Volunteers of friends and family were a big source of help in getting things done but nothing contributed quite so much as the sweat on the brows of Tom and Dale. Maker Works started paying rent in May of 2011. Paid staff came onboard in August. Their standard operating procedures were defined by September when they did a soft launch. Between then and May of 2012 they refined their operation and smoothed out the kinks. Then, after 18 months of hard work they held their grand opening on May 12, 2012.  3D Printer Build Group I had the pleasure of visiting Maker Works back in March. Going in, I didn't know it would be such a pleasure; it was just a side trip of my daughter's college visit to Ann Arbor. Frankly, we only hoped we’d find the space open and maybe get a tour. What we received was the undivided attention of Tom who gave us a tour, described his programs, and shared his vision. What we saw was a clean and fully fleshed out makerspace operating with a buzz of activity. One room was full of students actively working their FIRST Robotics entry. Another cavernous room had a woodworking project being milled on a full-size ShopBot. We couldn't help but feel a pang of desire when we passed through the crafts area and saw their laser cutter, sewing and embroidery machines, and 3D printers. The tour went on and on revealing great resources. At one point, I noticed private offices and asked about them. Since the start, they'd had small businesses and entrepreneurs asking to rent space and they were able to quickly rent out all unallocated space, even the office that Tom and Dale shared. When the lease for A2MechShop ended in April, Maker Works expanded into the rest of their building and A2MechShop moved in. Toward the end, Tom paused at a whiteboard to share his vision. All that we had seen was for a purpose. It was a business because it had to be self-sustaining and for that reason needed to charge a reasonable monthly rate for makers who should pay. However, students and people needing employment would also be included through a formula of lower rates and a jobs board which listed projects needing work. It’s possible to earn credit for education and membership by cleaning, repairing, teaching, and otherwise benefiting Maker Works with other tasks. The idea is that everyone should be able to benefit from Maker Works regardless of means, to learn new skills, to increase self confidence, and to benefit the community. Dale and Tom are determined to include, not exclude, people to help them realize their vision to benefit the world. And just how do they see themselves benefiting the world? They want to serve three distinct communities: makers, students, and 1099s (unemployed, under-employed, self-employed, independent contractors etc.). Their goal is to build and maintain an environment that nurtures Education and Innovation which in the end benefit the world by delivering skilled workers, new businesses, and great products. Below is Tom's diagram which summarizes the vision.  The Maker Works Vision So they’ve launched and they're humming along. What next? Well, if one Maker Works can do good in Ann Arbor then additional Maker Works can do good in other areas. They're interested in replicating the model in places with the need to bring training in modern fabrication and a workshop of tools to help with economic redevelopment. As Tom said to me, "Ann Arbor was a safe place for us to start but, in terms of impact, Downtown Detroit would be the ultimate. There are so many wonderful and committed people doing good there. It would be a dream come true to be a positive part of Detroit." They're looking for anyone interested in and able to apply their model of social entrepreneurialism to help solve problems. If you'd like to know more then visit their website: Maker-Works.com.

Or, if you're so lucky as to be in Ann Arbor then stop by.

However, plan better than I did and call ahead.

I’ve always been a fan of auto racing, engineering, and modifying things to go faster, so when I witnessed the Power Racing Series at Detroit Maker Faire last year I knew it was something special. What could be more exciting than racing modified Power Wheels vehicles around a track at break-neck speed? This year the PPPRS is planning three events in Kansas City, Detroit and Chicago. Due to all the costs incurred by the folks at Pumping Station: One, they’ve started an indiegogo campaign so we can help make the events possible.

We are the Power Racing Series.

Teams from across the country modify plastic electric ride-on vehicles (Power Wheels) into full-fledged sub-$500 racing machines. They hack their cars for drag races, crazy road courses and menacing endurance runs designed to bring out the engineer in everyone. However, we need your help. If we can’t raise enough funds through this campaign, we might not be able to operate this season at all. Your donations to this project go towards the following: - renting a timing and scoring system for the series

- constructing track-related infrastructure (podiums, lights & scoreboards)

- funding more safety equipment for the drivers

- affording basic travel and lodging expenses for our volunteers

- covering insurance and rental costsfor 3 races this season

Help make affordable electric racing machines possible!

So if you have a desire to build a vehicle, be in the pit crew, watch, or just want to support this great event, head on over to indiegogo or the PPPRS site. Donations start at $15 and all donation levels include fun perks. Hurry, the campaign to save the Power Racing Series ends Wednesday, June 20th!

For this year’s Father’s Day celebration, we’ve put together a set of downloadable cards that you can print onto card stock, cut out, and make into a little present to give to dad, some other maker in your life, or to keep for yourself. The three cards are: Basic Maker Skills for Kids, the Maker’s Checklist (for project planning), and the wildly popular Tips My Dad Says card (one of last year’s most popular posts/downloads on the site). We’ve even included a gift card that you can use. Your recipient can pin these cards up in a workshop or slot them into the pocket of a Maker’s Notebook. We hope the patriarchs in your life have a great day and that we can encourage you to celebrate the maker in them. We’ve started a fun conversation on the craziest thing dad ever built (or tried to build). You can add your stories here. We’ll wrap the best of these up on Sunday. Father’s Day Downloadable Gift Cards [PDF] More:

Check out all of this year’s (and previous year’s) Father’s Day content on MAKE

| |

No comments:

Post a Comment

Keep a civil tongue.